The Question posed on LinkedIn.

“We have all been working with the rationale that glass containers need to be depyrogenated. Depyrogenation meaning a measurable three log reduction of an initial concentration of Endotoxin.

We are now hearing about the impact of excess temperatures on the inner ‘skin’ of a vial and how some ‘hydration’ is lost when blasted with high temperatures and then we hear that after product filling, there could potentially be a ‘re-hydration’ of this ‘skin’. And finally all this dehydration and re-hydration potentially causing glass lamellae formation. (I am not a glass technologist, I’m groping around the dark here, feel free to correct any misconceptions!)

With all this concern about particulates, does it make sense to scale down glass vial heat treatments in SVP to sterilization temperatures rather than depyrogenation temperatures?

A vial which has been washed with a final rinse in hot WFI is not expected to have any significant level of endotoxin in it. Considering the volume adminstered, doesn’t it make sense to move to concentrating on sterilization rather than depyrogenation of an unrealistically large quantity of endotoxin load?”

My advice:

Yes. You must depyrogenate your containers where the product is being injected into the customer and regardless of rinsing or dry heat, you have to show you can remove pyrogens from your containers.

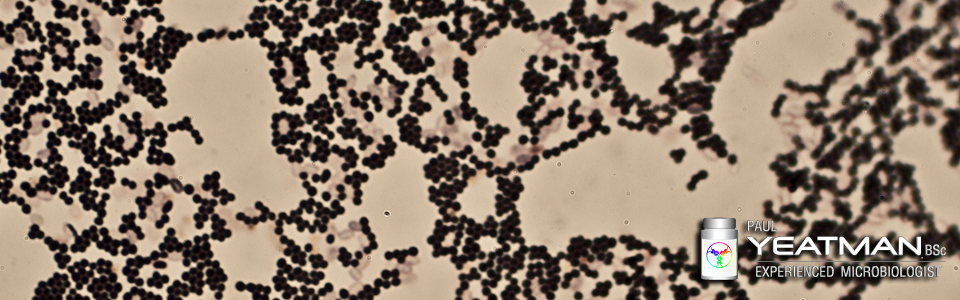

It would be UNWISE to use a sterilization protocol in an attempt to dehydrogenate your glassware if that if what you are suggesting. Pyrogens from when G- bacteria are destroyed. You need to physically remove them or “char them to death” for want of a better term. Using a sterilization to remove pyrogens will ultimately lead to dead customers and your company being severely affected.

You could scale back your temperatures when using a DHO as there is a range of temperatures allowed. Lower temperature equals longer exposure time. If your company is happy with the increased time it takes to make batches, then you could validate your new process and take it from there. If it is an amendment to your current process, then if it is a big enough one, you’d need to alter your product registration.

Regarding temperature effects on your vials. I’d examine where you heard the information and determine if they are a reputable source, determine what other companies are doing (and if the regulatory bodies have said that that’s an acceptable standard practice) and either enlist the services of an expert or conduct your own experiments.