This was repurposed into a LinkedIn article as part of my Developing My Writing While Helping Others series.

What Is Viable Environmental Monitoring (VEM)?

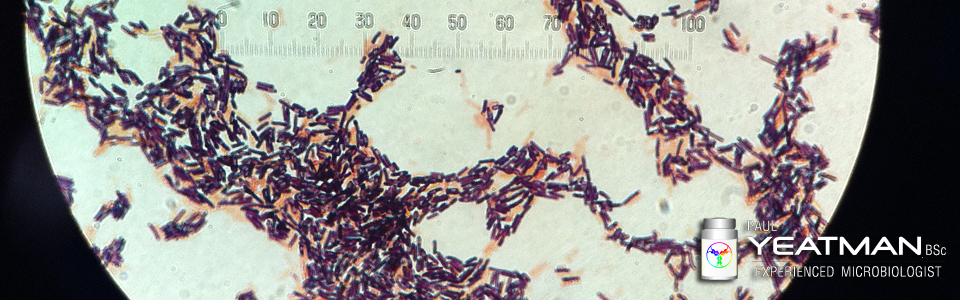

Viable Environmental Monitoring (VEM) is the monitoring of factors within a production environment that may have an impact on the quality of goods produced within the environment. Typically this is any physical object than could support or introduce microbial contamination to a manufacturing environment: air, gases, surfaces (both on introduced objects and within the production room), liquids and people. This discussion does not extend to Environmental Monitoring such as particle counting, temperature, pressure differentials, etc.

Why Is VEM Needed?

VEM is used to determine if the controlled environmental being monitored is within an adequate state of microbiological control (i.e whether or not the area meets the specifications as described in the site quality manual, product registration dossiers and associated documents) . It may also be used to confirm that cleaning and sanitation is effective (and being conducted as specified) and that personnel within the production environment are not carrying an unacceptable bioload or inadvertently causing contamination. This is required information as it ensures that products produced are unadulterated and are fit for their intended purpose.

Types of VEM?

Across the pharmaceutical industry there are several acceptable recovery methods:

- Active air samplers

- Passive air sampling (losing favor)

- Contact or RODAC plates. Info: Replicate Organism Detection and Counting

- Swabbing

- Print plates

Not directly related to the physical state of a clearoom, though still an important part of a VEM program is the monitoring of:

- Water for Injection

- Pre and post fill materials

- Containers and stoppers

Each recovery method is specific to a certain sample type and prior to initiating any EM program, one needs to determine how and what to monitor. The food manufacturing industry uses a scaled down version of VEM.

How To Determine What To Monitor (and with what and when)?

This can be long an involved for a sterile facility, or fairly basic for a non sterile facility and is primarily dependant on the what could happen if microbes were present in the product at end-user stage and follows a risk based approach.

What to monitor is based on:

- Risk to product

- Classification of clean room

- Type of product manufactured

And looks at the following factors:

- what the room is used for

- classification of room

- if room needs to be sub divided

- each activity in the room

- how each activity impacts on every other activity

- how each activity impacts on the product

- what can be monitored to capture the said activity that may impact product quality

- how best to monitor these sites

- when is best to monitor these sites (eg during aseptic setup or post fill)

You may also wish to consider common production areas that may impact on the room being monitored and whether they need to be sampled in conjunction with the room being examined.

For a sterile product, air and product contact surfaces are considered more critical than non product contact surfaces and thus have to be monitored. This may also extend to personnel, equipment used to manipulate product containers, gas lines. Particle counting may also be required as well as regular dummy runs using sterile media in place of actual product. Each separate batch of product made (including each shift) typically needs a set of VEM data.

For a non sterile product, the VEM requirements are less regulated and it is primarily left up to each manufacturer to determine what and how to monitor. For example, a non sterile facility may only require the monitoring of the air in various production rooms once a month with a small number of surface samples from rooms deemed to represent “worse case”.

For a large room, subdivisions based on size as well as the placement of laminar flow hoods may be required.

Regardless of the amount of sampling, the rationale behind what is sampled, how it is sampled, and how often it is sampled should be documented as part of the facilities EM commissioning program.

What are Alert and Action Levels?

Alert and action levels exist in order to determine if a production environment is within a state of control.

An alert level is normally based on historical data that indicates when an area is deviating from the normal levels of microbes, but as yet, a risk to the product not high. When an alert is produced, minimal actions are taken to fix the issue.

An action level is in place to show when a controlled environment is no longer in a state of control. When this level is breached, there may be a large risk to the product and thus to the end-user. When an action is produced, a product is put on hold until an investigation is conducted to determine the cause of the action, how it may affect the product, and the risk of releasing the affected batch for sale. The worse case scenario from an action result is a dead customer.

The various regulatory bodies have specified maximum levels for microbial contamination which cannot be breached. Best practice would be to set your levels below those required by the regs.

Why Validating Recovery Methods Is Wise Vital?

Once you decided how to monitor, you need to show that you can recover viable microbes – sampling is not enough and lots of pristine looking data will have an auditor pondering this.

Appendix:

- USP <1116> Microbiological Evaluation of Cleanrooms and Other Controlled Environments

- Guidelines on test methods for environmental monitoring

Did you find this informative or useful? Please consider a small donation so I can expand and improve on what I deliver.